Super strong artificial silk? That’s so metal.

Giving revamped silkworm silk a metallic bath may make the strands both strong and stiff, scientists report October 6 in Matter. Some strands were up to 70 percent stronger than silk spun by spiders, the team found.

The work is the latest in a decades-long quest to create fibers as strong, lightweight and biodegradable as spider silk. If scientists could mass-produce such material, the potential uses range from the biomedical to the athletic. Sutures, artificial ligaments and tendons — even sporting equipment could get an arachnid enhancement.

“If you’ve got a climbing rope that weighs half of what it normally does and still has the same mechanical properties, then obviously you’re going to be a happy climber,” says Randy Lewis, a silk scientist at Utah State University in Logan who was not involved with the study.

Scrounging up enough silky material to make these super strong products has been a big hurdle. Silk from silkworms is simple to harvest, but not all that strong. And spider silk, the gold-standard for handspun strength and toughness, is not exactly easy to collect. “Unlike silkworms, spiders cannot be farmed due to their territorial and aggressive nature,” write study coauthor Zhi Lin, a structural biologist at Tianjin University in China, and colleagues.

Scientists around the world have tried to spin sturdy strands in the lab using silkworm cocoons as a starting point. The first step is to strip off the silk’s gummy outer coating. Scientists can do this by boiling the fibers in a chemical bath, but that can be like taking a hatchet to silk proteins. If the proteins get too damaged, it’s hard for scientists to respin them into high-quality strands, says Chris Holland, a materials scientist at the University of Sheffield in England who was not involved in the study.

Lin’s team tried gentler approaches, one of which used lower temperatures and a papaya enzyme, to help dissolve the silk’s coating. That mild-mannered method seemed to work. “They don’t have little itty-bitty pieces of silk protein,” Lewis says. “That’s huge because the bigger the proteins that remain, the stronger the fibers are going to be.”

Scientists can spin artificial silk fibers (pictured) that are strong and tough using a method that involves a metal ion bath.J. Wang et al/Matter 2022

After some processing steps, the researchers forced the resulting silk sludge through a tiny tube, like squeezing out toothpaste. Then, they bathed the extruded silk in a solution containing zinc and iron ions, eventually stretching the strands like taffy to make long, skinny fibers. The metal dip could be why some of the strands were so strong — Lin’s team detected zinc ions in the finished fibers. But Holland and Lewis aren’t so sure.

The team’s real innovation may be that “they’ve managed to unspin silk in a less damaging way,” Holland says. Lewis agrees. “In my mind,” he says, “that’s a major step forward.”

A new treatment could restore some mobility in people paralyzed by strokes

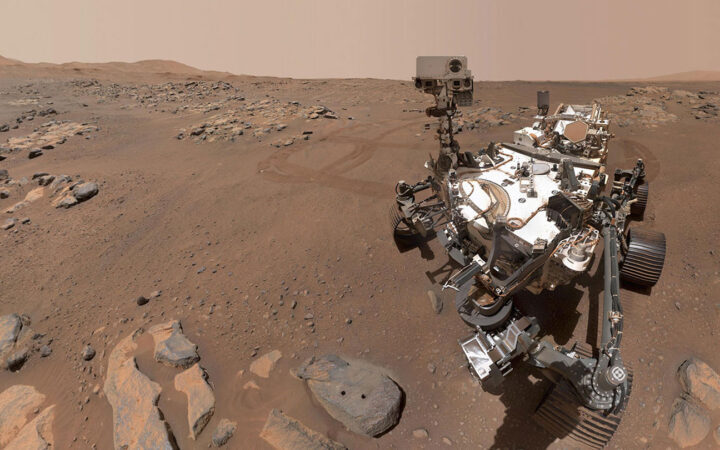

A new treatment could restore some mobility in people paralyzed by strokes  What has Perseverance found in two years on Mars?

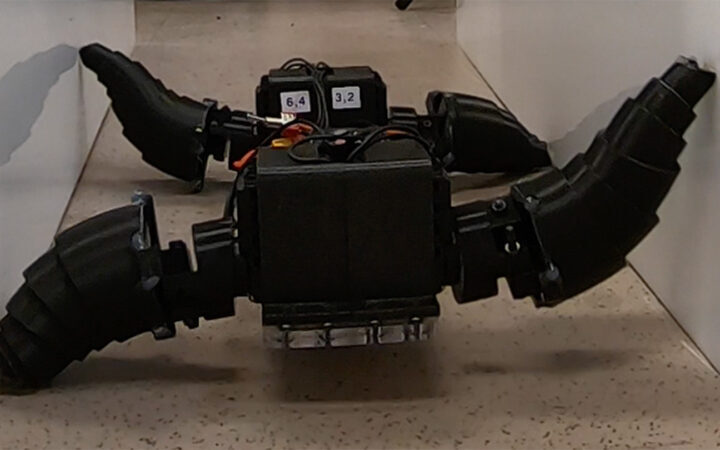

What has Perseverance found in two years on Mars?  This robot automatically tucks its limbs to squeeze through spaces

This robot automatically tucks its limbs to squeeze through spaces  Greta Thunberg’s new book urges the world to take climate action now

Greta Thunberg’s new book urges the world to take climate action now  Glassy eyes may help young crustaceans hide from predators in plain sight

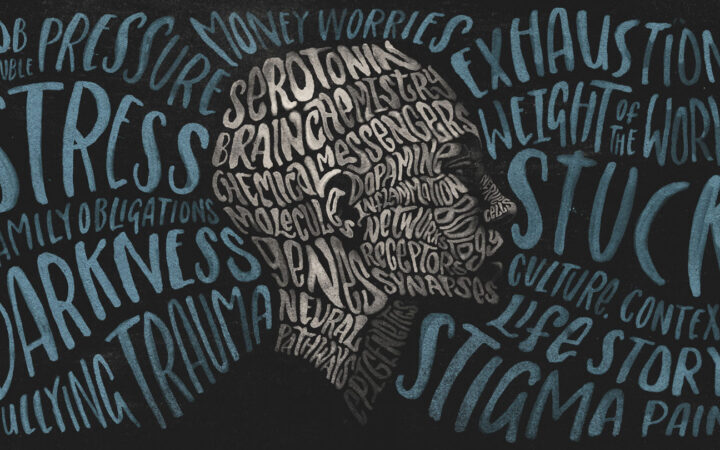

Glassy eyes may help young crustaceans hide from predators in plain sight  A chemical imbalance doesn’t explain depression. So what does?

A chemical imbalance doesn’t explain depression. So what does?